Contents

Types of Deep Foundation and Their uses in Construction

Read Also: Difference Between Shallow Foundation and Deep Foundation

Types of deep Foundation

- Pile Foundation

- Pier Foundation

- Well Foundation

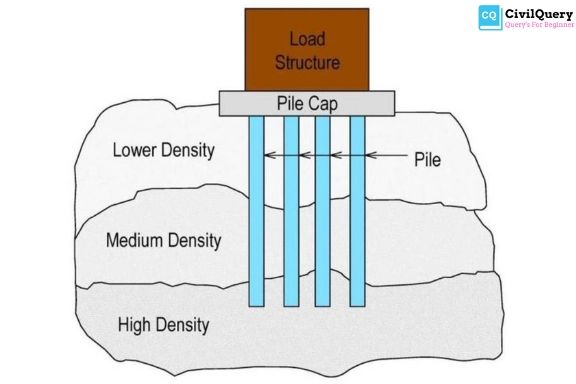

1. Pile Foundation

In this type of foundation, the load is transmitted by a vertical member. This vertical member is known as a pile. These piles are generally made of steel, concrete and wooden. These days precast members are used but we can create these members on site as well.

Classification of pile Foundation

- According to function

- According to material

1. According to function

It is subdivided into two types they are as follow

- Bearing piles

- Friction piles

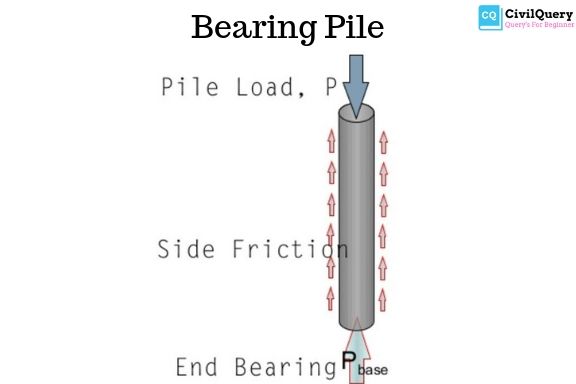

1. Bearing pile

They are driven till hard Strata or layer of Rock beds. The load is transmitted by columns to the hard layer of soil.

2. Friction pile

These piles are used where the soil is soft at a considerable depth. The load is transferred to the soft soil due to the friction produced between the soft soil which is in contact with these piles.

2. According to material

It is further divided into four types they are as follows

- Concrete pile

- Wooden pile or Timber pile

- Steel pile

- Composite pile

1. Concrete pile

The piles which are made with the help of concrete are known as concrete piles. The diameter of these pile varies from 30 to 50 cm. Minimum length of these pile is not taken less than 20 meters and maximum it can be taken till 30 meters.

Concrete piles are manufactured by following two types

- Precast (Ready Made)

- Cast in situ

1. Precast (Ready Made)

These piles are manufactured in the factory which is further transported to the construction site where ever it is required. These piles can bare load up to 800 KN.

Types of Deep Foundation and its Advantages and Disadvantages

Advantages of precast piles

- It saves our time as these piles are ready to install.

- By using these piles the construction is done at greater speed.

- For these piles, deep excavation is not required.

Disadvantages of Precast Piles

- These concrete piles are costly.

- As these precast members are prepared in a factory and then they are transported to the construction site the transportation charges are also added which increases the ultimate cost of these piles.

2. Cast-in-situ

These piles are made or manufactured on site where it is to be installed. So it saves money as the transportation cost is reduced. These files bare load up to 750 KN.

Read Also: What is a shallow foundation? Types Of Shallow foundation.

Civil Query

Read Also: Why Steel Is Used in Construction? Structural Steel Types.

2. Wooden or Timber piles

As the name suggests these piles are made up of wooden so they are known as wooden or Timber piles. For these piles, seasonal Timber wood is used. The diameter of the timber pile varies in between 20 to 50 cm.

Length of a pipe is taken 20 times that of its diameter. (For Example – 25 cm is its diameter. Then, L = 20 x 25 = 500 cm). The maintenance cost of these piles is more because as it is wood if it comes in contact with water then it can be damaged by fungus or white ants. So care has to be taken.

3. Steel piles

These files are generally in shape of ‘I’ or hollow section. It can be easily driven in the soil because it has a very small cross-sectional area. These piles can be used as a bearing pile but cannot be used as friction piles because if we use them as a friction pile it can sunk in the soil due to structural load.

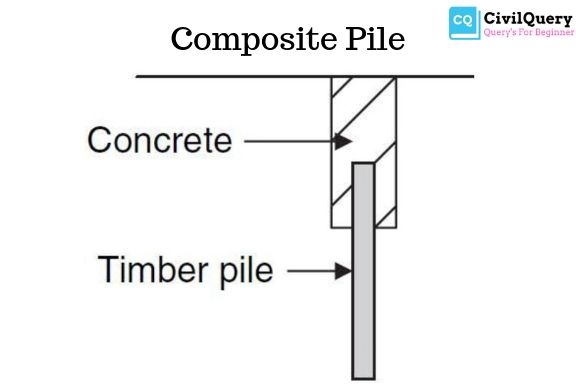

4. Composite pile

When the piles are made from more than one material they are known as composite pile. These piles are made from concrete and wood. These piles are used in those areas where the water table is up. These piles are used in such conditions just because concrete and wood both are good water absorbers.

Advantages of Pile Foundation

- Use of these piles can save time.

- They are very much economical.

- By using this pile system it reduces the needed excavation.

- Pumping of water is not required as we are not excavating much in soil.

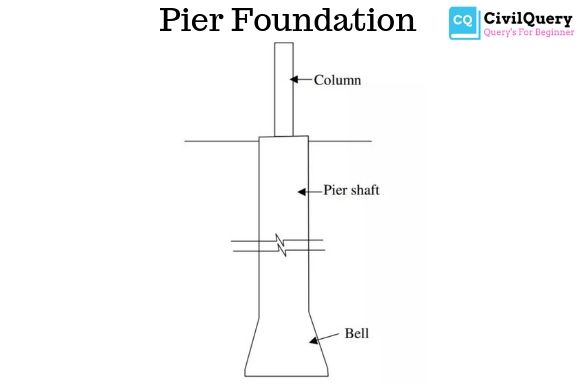

2. Pier Foundation

A pier Foundation is a vertical column of relatively larger cross-section than a pile. The load coming from the superstructure is carried to the hard strata through these vertical columns. They are generally cast on site. A pier is installed in dry area by excavating a cylindrical hole. If the diameter is greater than 0.6 m or equal to 0.6 meters then it is termed as a pier.

Types of Pier Foundation

- Masonry or concrete pier.

- Drilled caissons.

1. Masonry or concrete pier

This type of footing is chosen when the depth of the hard strata is at 5 meters or less than 5 meter. Also, this type of footing is done when not much heavy load is coming from the superstructure.

The masonry work is done by brick or concrete. The size of excavation depends upon the level at which hard strata exists. The size and shape of these masonry or concrete pier depend upon the level of hard strata is present.

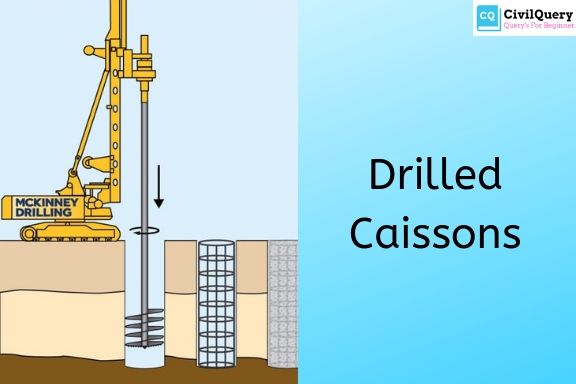

2. Drilled Caissons

They are mainly in a cylindrical shape so they are also known as cylindrical foundations. Distribution for drilled caissons is generally carried out by drilling process. This foundation work as a compression member. The lord acted on top of these members, so we can say that they are subjected to axial load and which is further transferred to hard layer of soil.

Drilled Caissons are classified into three categories

- Concrete caissons with enlarged bottom.

- Caissons of steel pipe with concrete filled.

- Caissons of steel pipe with concrete and steel core.

1. Concrete caissons with enlarged bottom

In this at top which is at ground level of cap is provided. Above that cap brickwork is carried out. Below this cap a pier is constructed which is further followed by the enlarged bottom which is also known as bell. The angle of this bell at bottom is 60 degree.

2. Caissons of steel pipe with concrete filled

In this also at the top which is at ground level, a cap is provided. Below this cap, at both extreme ends, a steel shell is created. This steel shell is the outer portion. Inside this steel shell concrete is filled.

3. Caissons of steel pipe with concrete and steel core

The assembly of this type is also the same as the caissons of steel pipe with concrete-filled. But the only change is that in the central portion of the steel core or a rod is fixed which gives more stability to the structure as the weight taking capacity increased due to the steel core.

Thank u for shearing your artical Foundation | What is Deep Foundation…..?

one type of deep foundation is missing in this web

well foundation