Contents

What is Lintel?

A lintel is a prevalent part of the building. It is a horizontal member which rests on the door or window opening to support the portion of the structure above it.

Whenever openings are made in the wall there is a concentrated force above the opening thus, the function of the lintel is the same as a beam, it transfers the structure load to its supports.

These beams are used to support the wall above the openings like windows and doors portals etc. and so forth are necessary to be provided in a building structure. These beams are provided as a safeguard of doors and windows.

Imposed loads coming from above blocks or bricks are taken by these beams. The load is transferred to the side walls. Sometimes lintels are used as decorative architectural elements.

It is generally camouflaged within the wall and is of the width as that of a wall. Instead of beams some wooden material is used generally called header

Types of Lintel Beam

- Timber or wood Lintel

- Stone Lintel

- Brick Lintel

- Steel Lintel

- Reinforced Concrete Lintel

- Reinforced Brick Lintel

1. Timber Or Wood Lintel

The use of wood/ timber in ancient times was very common. Over time this type of lintel has been replaced with many advanced technologies and durable materials. In hilly areas where timber availability is not rare, this type of lintel is still used.

The downside of using timber or wood as a structural member is that due to prolonged exposure to the atmosphere, wood is susceptible to decay thus causing failure in the building structural system.

Another disadvantage of using wood is cost. The cost is huge, and the durability is not guaranteed. Timbers are structurally not a reliable material. If proper ventilation is not provided, it may rot down.

Wood is combustible thus susceptibility to catching fire is high. Very often, timber is used along with steel plates at the top and bottom, these are called flitched beams or composite beams.

2. Stone Lintel

This type of lintel is used where stones are available abundantly. Uniform rectangle bits are required. The main advantage of using this type is the length available is larger than the timber lintel.

The use of stone lintel is intrinsically bound to the use of stone masonry must be homogenous and it cannot be heterogenic construction (i.e., use of stone lintel in a brick masonry wall.)

The use of stones for lintels must be done with a good understanding of the layering of stones and the types of bonds it creates. The thickness of lintel governs the design of lintel.

The Thumb rule followed for the thickness of construction is 4cm per 30cm of lintel length. Along with skill few other drawbacks of using stone, the lintel is that it cannot stand transverse stress.

Stones being weak in tension, this type of lintel is not used in the buildings with vibratory loads i.e. susceptible to the earthquake. Transportation of stones is cost-consuming.

Read Also:

- Sustainable Building Practices for Relocating to Eco-Friendly Communities

- Seismic Design and Earthquake-Resistant Construction Methods

- The Importance of Soil Testing Before Building Your Home

- Reasons Why You Should Choose MDF Skirting Boards

- How to Start Your Career as a Civil Engineer A Guide for Beginners

- The Importance of Structural Engineering in Construction

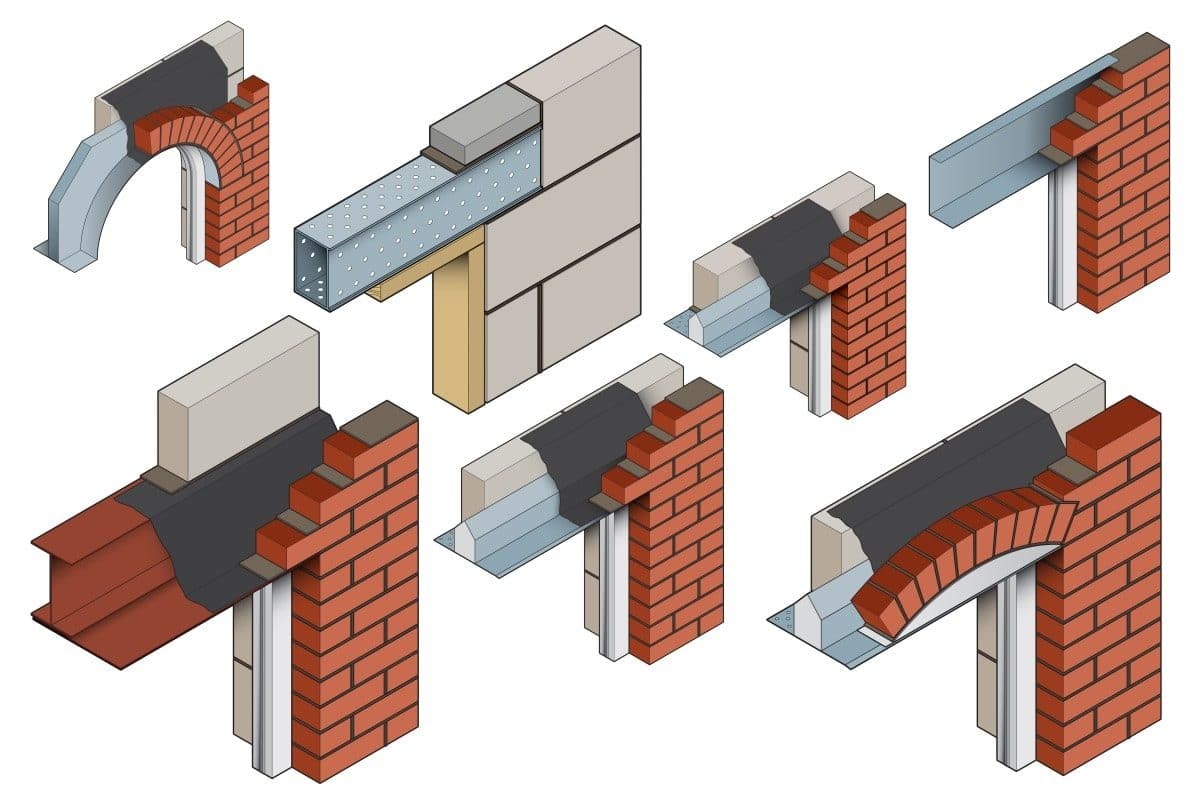

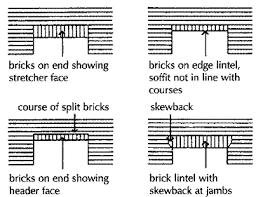

3. Brick Lintel

Bricks used for this type of lintels are well burnt. The bricks used are hard and robust. It is used for small openings i.e. less than 1m where the load is less heavy.

The depth of lintel varies from one brick thick to two brick thick i.e. 10cm to 20cm. To increase the shear resistance of brick, the frog of the brick with mortar at end joints. Curing of a minimum of 10 days is required for the bonds to have complete strength.

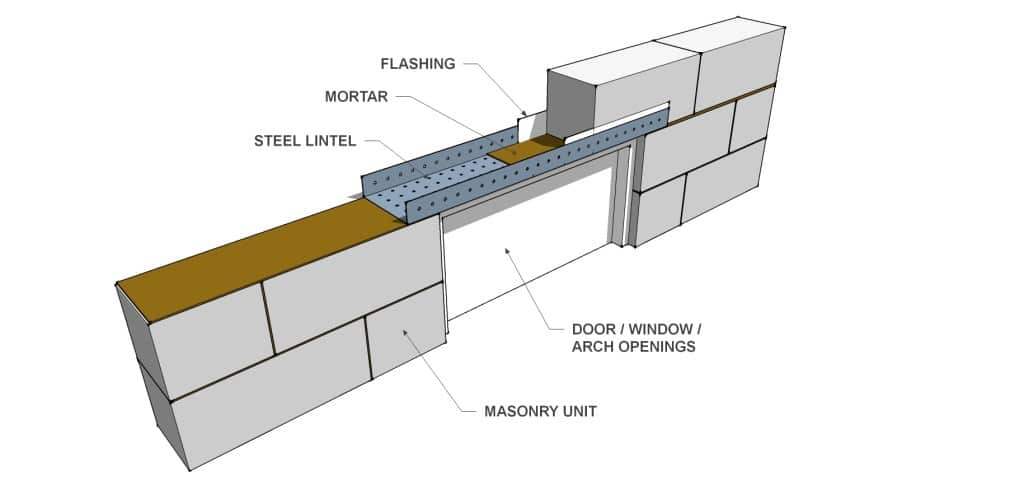

4. Steel Lintel

These types of lintels are adopted in design when loads superimposed are heavy and the opening gaps are considerably large. When the loads are heavy the depth of lintel plays a critical role thus depth cannot be ignored.

Rolled steel joints or channel sections are important structural members of steel lintel, these can be used singly or in the combination of two or three units depending on the overhead loads.

Steel lintel can be a combination of a single section or two or more sections they are either directly embedded in cladding where stone masonry is used or in concrete.

When two or more sections are used as lintels, a tube separator is used to keep the two intact in a position. Curing is not required; thus, it can be ready to use immediately. The considerable downsides of these lintels are negligible.

They are cost-effective, can take heavier loads, and do not have external strengthening requirements, they are unaffected by rust, impervious to erosion and distorting, and are less labor-intensive.

5. Reinforced concrete lintel

The use of concrete for structural purposes is a general and common practice these days. As concrete is less malleable, the concrete is reinforced with steel bars to overcome this issue.

Thus, reinforced concrete structures are used these days. They can be used for larger spans and considerably heavy loads. 8cm per meter is the general practice for maintaining the thickness.

Precast or cast-in-situ are both available options for using reinforced concrete lintels on-site though, for larger spans, precast lintels are not advisable. In design loading, the magnitude and length of lintel govern the thickness of lintel.

The main advantage of using this type of lintel is that it is cost-effective, rigid, highly durable, has fire resisting properties, construction is easy and economic. Adaptability according to suitable size and shape is the huge upper hand in using RC lintels.

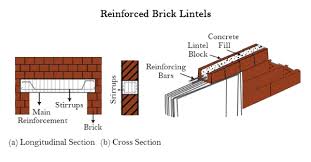

6. Reinforced brick lintel

If choosing brick lintel, the drawbacks of less load carrying capacity and to be used for smaller spans can be solved by using reinforced brick lintel. Generally, the thickness of this lintel is one brick thickness or multiple of one brick thickness.

Steel bars are inserted in the brick arrangement in the length direction. 1:3 cement mortar is used to fill the gaps between the inserted reinforcing bars and bricks. At every 3rd vertical joint, a 6mm diameter stirrup is used and for primary bottom reinforcement, 8mm to 10mm bars are used.

Lintel being a structural member must be checked at intervals for deteriorating and failure signals. The most common signals for failure include thinning because of pitting, step cracking around mortar joints.