As we know that concrete is very good in compression but it is not that good in tension. We get our required compressive strength without adding steel in concrete. But when we test concrete member for tensile strength without steel then the required strength is not achieved. So steel is used with concrete to make the concrete member strong in tension. This concrete member is known as RCC member.

Different Structural Steel Types

- 1. Mild Steel Bars

- 2. HYSD Bars

- 3. TMT Bars

- 4. TMX Bars

- 5. Micro-Alloying Steel Bars

1. Mild Steel Bars

As the name suggests mild steel bars are very light in weight as compared to other types of steel. It is used in such a structure where the structure is not exposed to the heavy load. When we look at this steel its surface is smooth and it does not have a rib on its surface so the bonding between this steel and concrete is not good. It is observed that when we prepare frame using this steel and it is used in any structural member then due to the loading action concrete sleeps due to lack of bonding between steel and concrete.

Tensile strength of these steel bars is also very low. In mild steel bars, carbon content is also very low. The value of carbon is about 0.05 to 0.25 which is very less. Due to which its ductility is more but the strength is less. If you try to bend these bars, it bends easily because its ductility is high but the strength is less. So, these days Engineers and Architects has prohibited the use of mild steel bars not only in heavy loaded structures but also in lightweight structures.

Read Also: What is Formwork in Construction? | Types of Formwork

2. HYSD Bars (High Yield Strength Bars)

In this bar’s “Y” indicates the “Yield” strength of the bar. The yield strength of these bars is high. These types of bars are used for lightweight structures as well as heavy loaded structures. When we look at the surface of this bar, it has ribs on its surface. Due to this rib, the bonding between the steel and the concrete is very good as compared to mild steel bars. So, if the structure undergoes any structural moment or if the structure is exposed to an earthquake it is able to sustain this structural moment. So, the durability of the structure increases. The carbon content in HYSD bars is more so the strength is more but the ductility is less. These days about 95% of the steel used is HYSD bars for any type of construction.

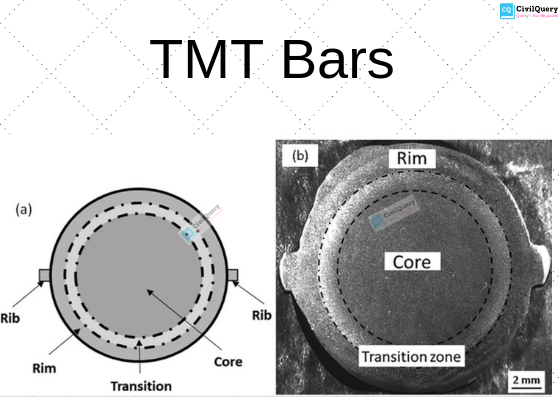

3. TMT Bars (Thermo Mechanically Treated Bars)

TMT Bars are known as Thermo Mechanically Treated Bars. If we look at the cross-section of these bars, we can see that the outer portion of these bars is hard and the inner portion is of soft material. The outer portion of these bars also has ribs on it so the bonding between steel and concrete is as same as High Yield Strength Bars. As the inner portion is of a softer material so it provides better flexibility to these bars. Its weld-ability, durability, tensional and these bars are provided with anti-corrosion coating on its surface.

Read Also: Types of Deep foundation and its uses in construction

Read Also: What is shallow Foundation? Types of Shallow Foundation.

CivilQuery

4. TMX Bars (Thermax Powered Bars)

TMX Bars are known as Thermax Powered Bars. These bars are Germany based bars and these are also known as new generation bars. Overall if we compare the manufacturing stats then we can see that 40% of the manufacturing is carried out in India and the other remaining 60% is done world-wide. These bars provide a good amount of resistance during earth-quack. It provides good weldability, ductility, tensional. These bars are proven more heat resistance bars because they can withstand 5000°C of heat. During the fire condition, these bars provide additional benefit to the structure. The cost of these bars is very high so it is not used in normal buildings or structures. It can be used in structures like bridges, big monuments, etc.

5. Micro Alloying Steel Bars

Normally the carbon-based steel bars are added with mix metals in a very small amount to boost up the properties of the carbon-based steel bars. These types of steel bars are known as microalloying steel bars. The percentage of mix metals added is about 0.05 to 0.1%. The metals which are used as alloying material are Niobium, Vanadium, Titanium, Zirconium, Boron, etc

3 thoughts on “Why Steel Is Used in Construction? Structural Steel Types”