Contents

What is the fineness of the cement?

A Fineness of Cement is Measure of the size of Cement Particle, and it is described in terms of the specific surface area of Cement particle. The Fineness of cement can be Calculated by particle size analysis, by using the air permeability method, by using sedimentation method.

How the size of Cement Particles affects the effects the hydration of Cement

To begin with, let’s understand how the size of cement particles affects the hydration of the cement.

Size of Particles – If the size of a particle is small i.e. fineness is high then the hydration process will be fast. Let’s understand this by considering two cement particles of different sizes i.e. large particle and small particle.

A Large Particle of Cement

Large Particle of Cement – If we have OPC cement with larger particles, so we call this large particle as a lump. In this lump, other particles are also present in the inner surface (Refer drawing for better understanding).

When we pour water on it the water first forms a film over the surface of the large particle and reacts with the particles present on the outer surface. Then the water penetrates into the large particle and reacts with the other particles. This process is known as the hydration process which is slow due to the particle size.

A Small Particle of Cement

Small Particle – If we have OPC cement with small or fine particles then these particles are unattached to each other. So, when we add water into it this water reacts with these particles simultaneously as these are not attached to each other.

So, in these types of cement particles, the hydration process is fast as compared to the large particles. But it does not mean that the final strength of the concrete will be increased.

Final strength depends on the chemical composition due to which the final strength is going to be more or less. If the size of the cement is small or finely grinned then the initial setting time will be less. The final strength will be the same in both cases.

i,e

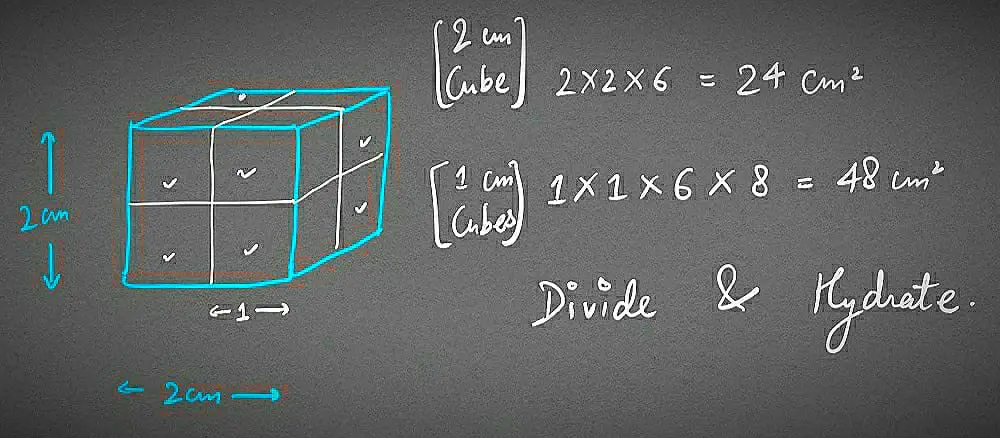

For Example: If the surface area is more than the hydration process is high. Briefly explained below.

If we consider a cube of size 2cm x 2cm. So, the surface area of the cube is 24 cm2. This cube is further divided into 8 parts. Now, the size of the cube 1cm x 1cm. So now the surface area is 48 cm2 it just doubled from the first cube. Therefore, the increase in surface area faster the hydration process.

1. Better cohesiveness of concrete.

2. Reduction in bleeding.

3. Increase in heat generation.

4. Increase in shrinkage and cracking.

5. Better contact with water.

6. The initial strength gaining process accelerates.

7. Ultimate strength remains constant.

1. Blaine air permeability test of cement.

2. Wagner’s turbidimeter test.

3. Particle size distribution method.

4. Lea & nurses air permeability test of cement.

Blaine air permeability test of cement.

Aim: To determine the fineness of cement by determining specific surface by Blaine’s air permeability method (IS 4031 – 1958).

Apparatus:

Permeability cell (12.5 +/- 1.0) mm diameter & (50 +/- 1.0) height, Plunger, U-Tube manometer, Perforated metal disc (1.0 mm) Perforation, Filter Paper disc (No.40 Whatman), Stop coak connected to U-Tube manometer and pressure bulb connected with a rubber bulb to the U-Tube manometer.

Time needed: 1 hour

Procedure:

-

Initially apply oil in the inner portion of the permeability cell and on the surface of the plunger. Then place the perforated metal disc into the permeability cell, over the metal disc place filter paper.

-

Then take the calculated amount of cement to say 2.8 grams and place this cement in the permeability cell. Then take the plunger and press the cement placed in the cell until the collar comes in contact with the top of the cell.

-

Now connect the permeability cell to the U-Tube manometer with the help of rubber coupling.

-

Open the stop clock and press the pressure bulb, due to this water present in the tube will start to depress.

-

Close the stop clock when the water reaches the bottom mark AA’.

-

When the water touches the second mark BB’ start the stopwatch, then the water starts moving towards CC’.

-

When the water touches the mark CC’ stop the stopwatch and note the time ‘T’ in seconds.

-

We have to carry out three observations amongst these 3 observations minimum of three observations must be taken for the average value of ‘S’ specific surface area of cement.

-

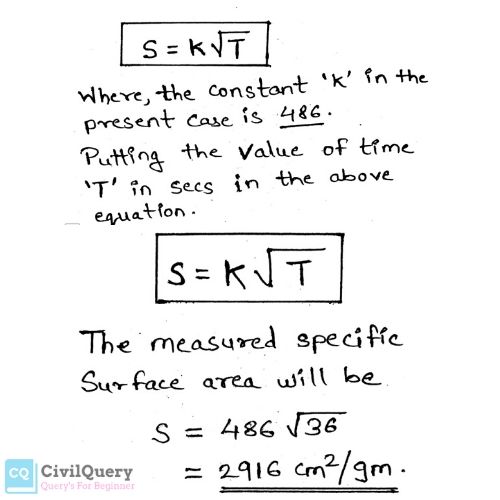

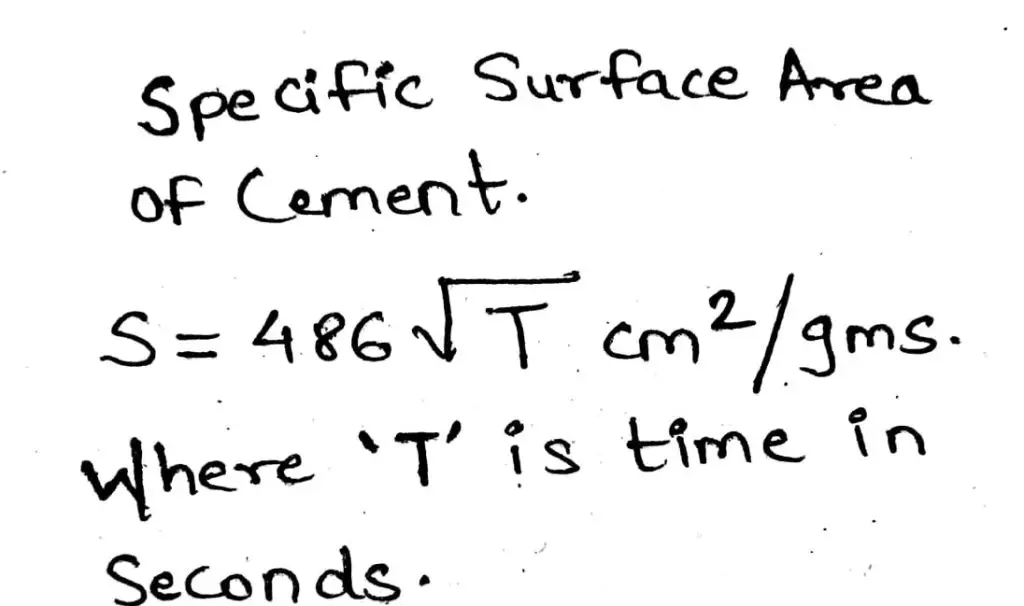

To determine specific surface area ‘S’ we have to follow the following equation.

-

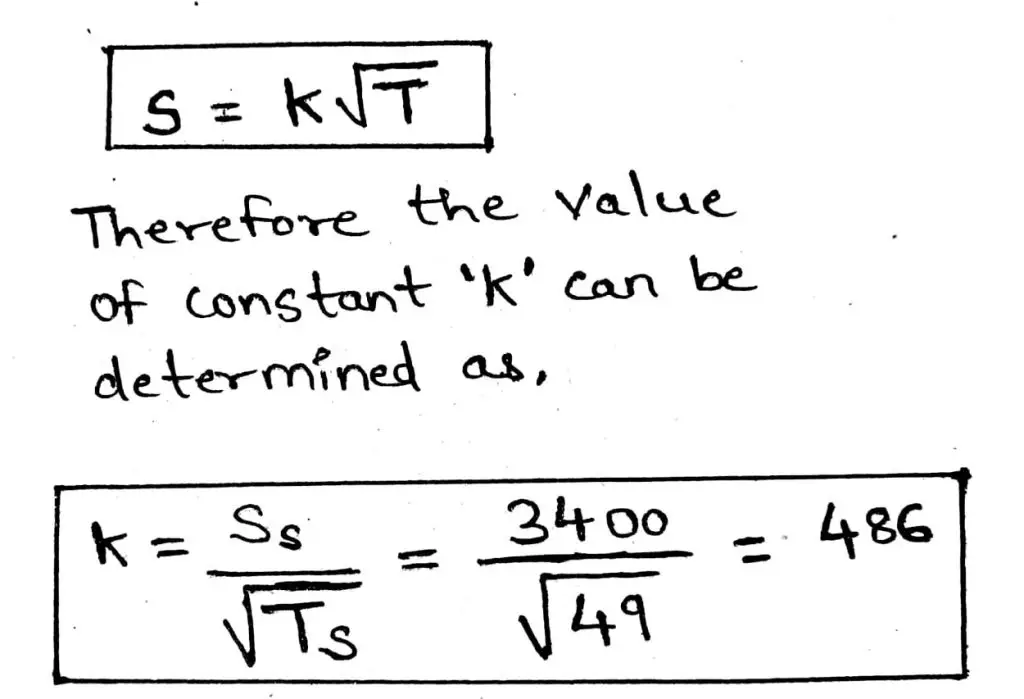

The value of constant ‘K’ can be determined by using a standard cement of known specific surface area and measuring the value of ‘T’ for a standard weight of cement which is normally taken as 2.8 gms.

-

For the present case the specific surface area of standard cement is given as 3400 cm2/gm & the time ‘T’ is measured as 49 seconds

Therefore, the value of constant ‘K’ can be determined by the following equation.

Aim: To determining the weight of the cement sample to be tested for its fineness following steps are to be followed.

Procedure:

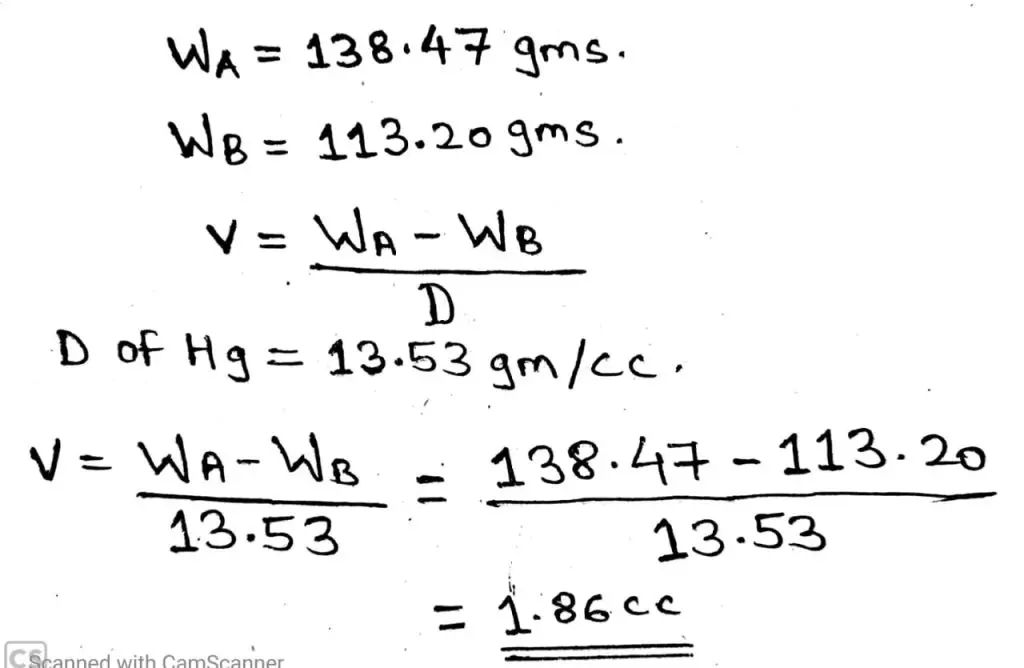

- Fill the permeability cell with mercury up to the top and level it with a small glass plate.

- Remove the mercury from the cell in a plate and record the weight of mercury with the plate and name it as ‘WA’.

- Measure 2.8 grams of cement sample and add it in the cell then place the filter paper on the top of it and press the plunger over the filter paper until its collar touches the top of the cell.

- Remove the plunger and fill the space with mercury then level it with a small glass plate.

- Now remove the mercury from the cell in the plate and measure the weight of mercury and plate and name it as ‘WB’.

- V = Bulk volume occupied by cement.

- D = Density of mercury.

The Bulk volume of cement calculated as follow

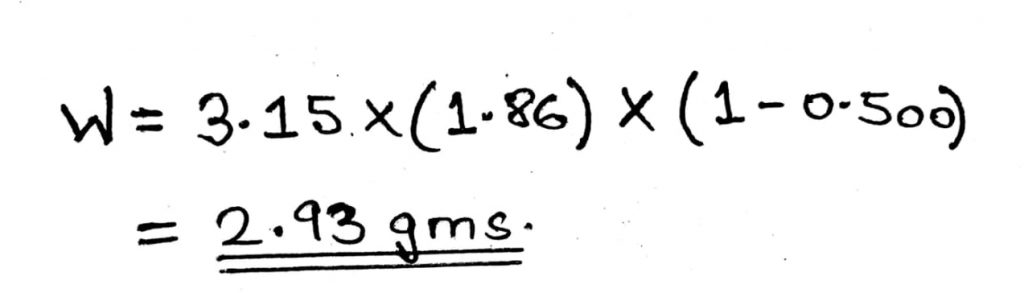

For calculating the weight of the cement sample required for the test using the below-given relation,

For the present case the weight of given Ordinary Portland Cement sample can be calculated as,

Once the weight of cement is calculated perform the experiment as described earlier and calculate the specific surface area of cement using the equation given below,

Conclusion: Blaine air permeability test of cement is important since it gives an idea of the size of smaller grains of the particles which play a major role in the process of hydration and strength development of the cement.

Wagner’s turbidimeter test

Aim: To determine the fineness of cement by Wagner’s turbidimeter test.

Apparatus: Beaker, kerosene, light bulb, photoelectric cell.

Procedure:

- Initially clean the beaker with a dry cloth.

- Then add kerosene in the beaker.

- Add cement in the beaker and stir it well. Due to which the turbidity of kerosene increases.

- Place the light bulb on one end of the beaker and switch on the connection.

- Then place the photoelectric cell exactly opposite to the light source.

- Then the light strikes on the photoelectric cell it starts inducing a current which is attached to a circuit that is programmed.

- Finally, we get the ‘S’ = specific surface.

3 Particle size distribution method.

Aim: To check the fineness of cement by particle size distribution method (Sieve Method).

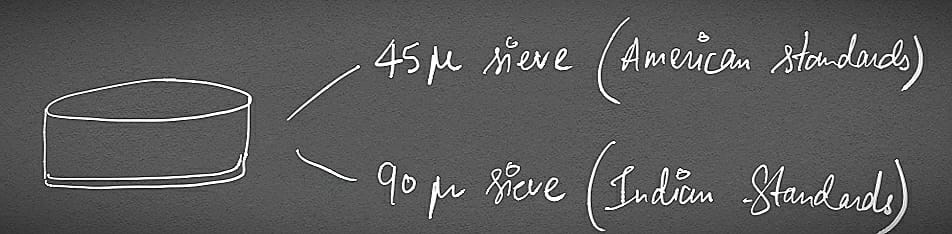

Apparatus: For (American Standards) 45 u (u = microns) sieve is used, For (Indian Standards) 90 u (u = microns) sieve is used, Pan, sieve cap and cement.

Procedure:

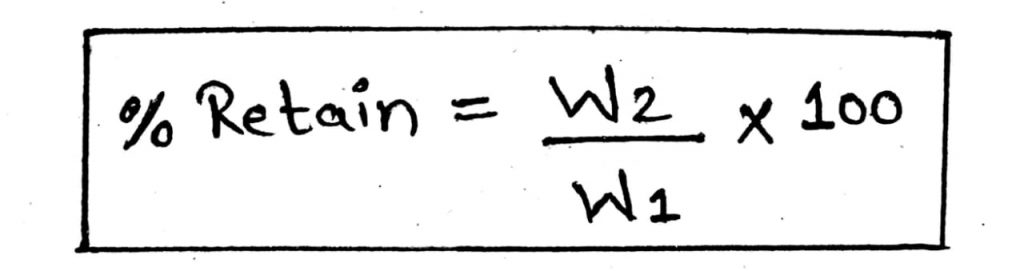

- First, take the cement sample of 100 grams ‘W1’

- Second, Then add this cement in the 90 u sieve and close the sieve with the cap.

- Third, then sieve the cement sample for 15 min to 20 min in clockwise, anti-clockwise direction, forward and backward direction.

- Fourth, then record the weight of the retained cement in the sieve as ‘W2’.

Result:

As per IS CODE

- For OPC cement percent retained weight must be 10% or less than that.

- For PPC, RHC and IRST-40 type cement percent retained weight must be 5% or less than that.

Lea & nurses air permeability test of cement.

Please refer to the PDF below

Why 2.8 gm cement is it fix???